Composition of Probe System:

RPS-L11 radio probe system include three pieces of hardware and one software package; The software package model is SP-W10, the two pieces of the hardware are:

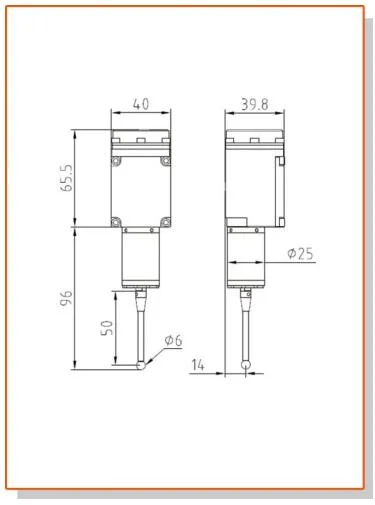

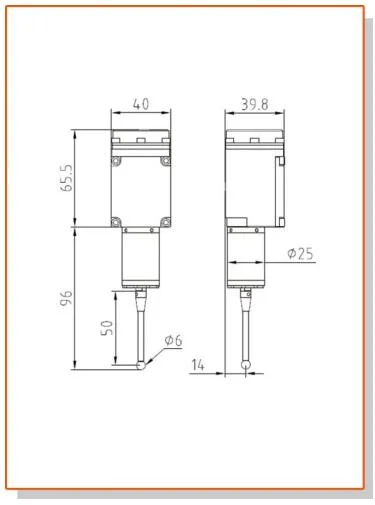

1)TP200 trigger probe unit(including optional stylus );

2)RPD/RPDM radio signal transmitter (including customizable mounting plate);

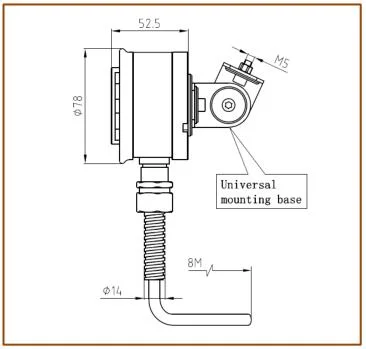

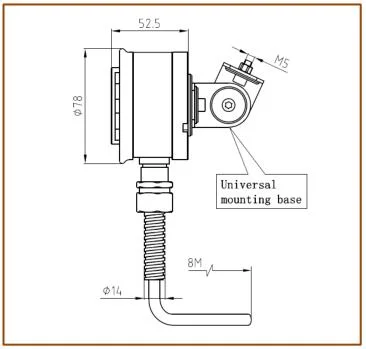

3)RSI-20 radio receiver(the standard cable length 8m/the optional lengthened cable).

Technical Parameters:

1)The technical parameters of TP200 trigger probe :

Stylus sensing direction: ±X, ±Y, +Z;

Stylus sensing over-travel : X-Y±15°, Z +5 mm;

The trigger force in Z direction: 1000 g;

Trigger force in X-Y surface( standard stylus ) : 65-130g;

Unidirectional repeatability(2σ): ≤ 2 μm;

Seal grade: IP68.

2)The technical parameters of RPD/RPDM radio signal transmitter:

Radio signal receiving/sending distance : ≥14 m;

Working days of new batteries (5% utilization rate in a single shift):280 days;

Seal grade: IP68.

3)RSI-20 radio receiver technical parameters:

Radio signal receiving/sending distance: ≥14 m;

Input voltage is 24±10% V DC and output load current is 50 mA.

Seal grade: IP68.

Technical Characteristics:

The stylus connector of TP200 probe is protected by a metal cover and a rubber seal cover;

Switch on/off method of RPD/RPDM radio signal emitter: M code on/off;

Radio code signals are used to transmit information between RPD/RPDM radio signal emitter and the receiver. The time to transmit and to decode a group of signals is less than 1ms;

The transmission frequency of the radio signal is within 2.4 G-2.483 G, the number of transmission channel is 84;

Output four kinds of SSR signals to machine control system when probe is in the states of trigger,error,probe batteries low and output pulse;

The RSI-20 receiver can change its logical state of the output signal by setting;

The indicating lights in RSI-20 and RPDM show the working status of the probe system.

Application:

Setting work-piece coordinate system and machining zero points automatically before processing;

Detect and control the key dimensions, position coordinates and their precision automatically between two processes;

Detect precision of the key dimensions,shapes, position after processing.

Applicable equipment:

Various specifications of CNC lathes, turning machine center, CNC turning-milling machine center.

RPS-L11 radio probe system include three pieces of hardware and one software package; The software package model is SP-W10, the two pieces of the hardware are:

1)TP200 trigger probe unit(including optional stylus );

2)RPD/RPDM radio signal transmitter (including customizable mounting plate);

3)RSI-20 radio receiver(the standard cable length 8m/the optional lengthened cable).

Technical Parameters:

1)The technical parameters of TP200 trigger probe :

Stylus sensing direction: ±X, ±Y, +Z;

Stylus sensing over-travel : X-Y±15°, Z +5 mm;

The trigger force in Z direction: 1000 g;

Trigger force in X-Y surface( standard stylus ) : 65-130g;

Unidirectional repeatability(2σ): ≤ 2 μm;

Seal grade: IP68.

2)The technical parameters of RPD/RPDM radio signal transmitter:

Radio signal receiving/sending distance : ≥14 m;

Working days of new batteries (5% utilization rate in a single shift):280 days;

Seal grade: IP68.

3)RSI-20 radio receiver technical parameters:

Radio signal receiving/sending distance: ≥14 m;

Input voltage is 24±10% V DC and output load current is 50 mA.

Seal grade: IP68.

Technical Characteristics:

The stylus connector of TP200 probe is protected by a metal cover and a rubber seal cover;

Switch on/off method of RPD/RPDM radio signal emitter: M code on/off;

Radio code signals are used to transmit information between RPD/RPDM radio signal emitter and the receiver. The time to transmit and to decode a group of signals is less than 1ms;

The transmission frequency of the radio signal is within 2.4 G-2.483 G, the number of transmission channel is 84;

Output four kinds of SSR signals to machine control system when probe is in the states of trigger,error,probe batteries low and output pulse;

The RSI-20 receiver can change its logical state of the output signal by setting;

The indicating lights in RSI-20 and RPDM show the working status of the probe system.

Application:

Setting work-piece coordinate system and machining zero points automatically before processing;

Detect and control the key dimensions, position coordinates and their precision automatically between two processes;

Detect precision of the key dimensions,shapes, position after processing.

Applicable equipment:

Various specifications of CNC lathes, turning machine center, CNC turning-milling machine center.